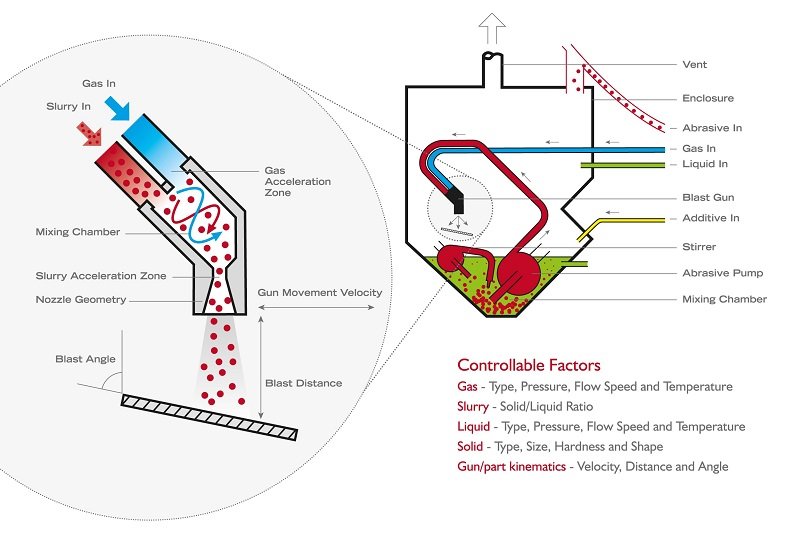

Wet blasting is the use of an abrasive media and compressed air to achieve a desired finish on a chosen surface.

Unlike dry blasting, wet blasting (or Vapor blasting to give it its other name) uses a third element – liquid – to enhance the levels of surface finish that can be achieved. The benefit of including water is a much smoother and more consistent finish.

Wet blasting was developed by Norman Ashworth in the early fifties; the introduction of water was originally as a response to the banning of silica in sand blasting, although the benefits of wet blasting far outweighed that of its predecessor.

By lubricating the abrasive particles in a buffer of water, Norman found that there was more of an even flow across the surface when using wet blasting systems. This is advantageous as it cause less damage to the substrate and any abrasive action is consistent across the whole surface.

In understanding this, companies can have much greater control over their surface finishing and this is something that Vapormatt prides itself on when it comes to wet blast systems design. We are world leading when it comes to the level of control users can achieve with our wet blasting or vapor blasting machines.

A range of abrasive media’s can also be used in a Vapormatt wet blasting system and this is determined by the type of effect or finish that is required. Typically users will opt for a silicon glass bead for a “polished” finish or an aluminum oxide to achieve a “cutting” effect that leaves a matt finish. However, various “special” abrasive medias such as ceramic, plastics and stainless steel shot can also be used on particular applications.