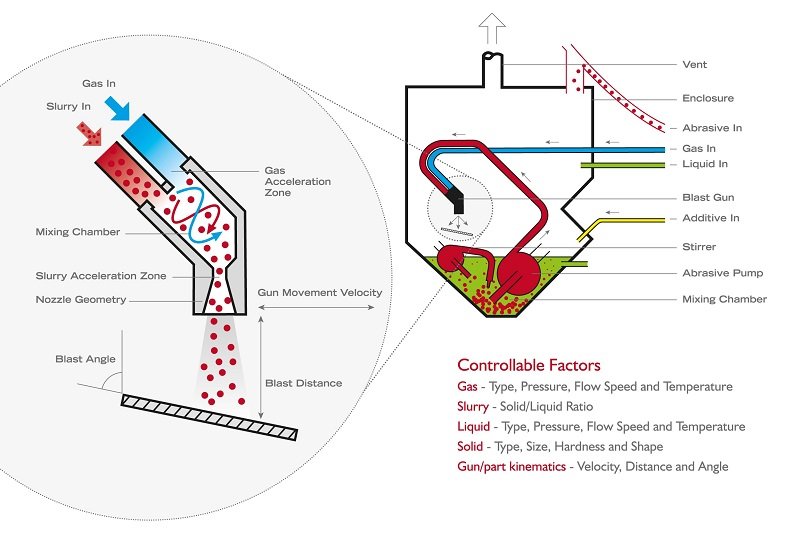

Sand blasting is the process of scrubbing the surface of any material by application of a propelling jet of abrasive substances (generally used sand) in order to smoothen or roughen the surfaces by filling layer of it.

The abrasive materials used must be more tough and hard than the material layered over the surface of the surface. As we know sand contains a crystal of quartz crystal & feldspar, which is number as 7 and 6 respectively Mohr’s scale, and have very good abrasive property.

Sometimes synthetic silica, carbon materials, silicon carbides, garnet are also additionally added in order to improve the quality of the abrasion.

Some major uses of sandblasting are:

- Sand blasting is often done before the application of paint. The rust, dust, and unwanted layers of paints can be easily removed with a jet of propelling sands. Sandblasting not only removes such layers but also roughen the surface by creating microscopic ridges and serrated lines because of which paint can easily form good adhesive bonding.

- Sandblasting with finer graded sands are also used to smoothen the surface of the piece of work of wood, metal plastic, resins, etc. which to give a shiny and smooth surface.

- It is very useful for the sophisticated and complicated geometry of materials or equipment where hand sanding is extremely difficult.

- Sandblasting corrodes the layer of material. So with help of sandblasting and different rough grade of sand, one can simply file the unnecessary surface material over the surface and also can provide smoothen shapes. However, the filing must be only within the limit of 2-5mm only.

Advantage of sandblasting

- It is a very easy, efficient, and time-saving method than sanding.

- The abrasive action of sandblasting is more even

- The sandblasting can be easily used to the corners and the sophisticated geometrical areas without much effort

- Sandblasting is a very powerful method so can even remove tough layers of concrete, slag of welded material, and highly adhered paint colors (like in the car)

- Sandblasting can be easily performed. Moreover, the abrasive material used is sand which is abundantly available in many parts of the world

Sand blasting have high efficiency, however it has several disadvantages to use. Come of them are:

- Sand blasting over the smooth area and hardened area like glass are not useful. As it is ineffective to such surface ad moreover they create a scratch over such a smooth surface.

- The residual dust remnants after sand blasting can cause pollution in the air. And also causes difficulty in breathing. the operator associated with it may have Respiratory Track Infectious disease.

- The use of silica might cause a siliceous hazard as the silica sand breaks easily causing a large amount of minute dust.

- There is a probability of harm by the rebounded abrasive material near the area. Thus the protective casing is used for small work however cannot be used for large voluminous works.

- The equipment might not be easily available and accessible. Moreover, it is not economic for small projects.High precaution measures are to be taken by operators.

- High precaution measures are to be taken by operators.