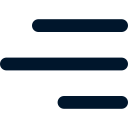

Abrasive

Garnet

| Sizes | 10-300 |

|---|---|

| Shape | x |

| Cost per use | Med |

| Hardness | 8 Moh |

| Applications | Coating Removal, Grinding Wheels, Sandpaper, Surface Cleaning |

| Industries | Civil Infrastructure, Heavy Equipment, Industrial Fabrication, Marine & Ships, Oil & Gas |

| Pros | Corrosion resistance, Low dust emission |

| Cons | – |

| Recomendation Equipment & PPE | – |

Description

| Size | Application |

|---|---|

| 16 | Heavy mil scale and rust removal. |

| 36 | Used to remove mil scale, rust and thick coatings. |

| 80 | Used on new steel and aluminium for light rust or thin coatings |

| 16/24 | Used to remove heavy mil scale, rust and thick coatings. |

| 30/40 | Heavy coating and rust removal while maintaining profile. |

| 30/60 | New steel and coating removal with consistent profile. |

Modern industry relies on high quality garnet in a host of different milled specifications for applications as varied as sand blasting, solvent filtration and industrial flooring. Both wet and dry blasting applications can use garnet abrasive. Blasting with garnet abrasive can be used for surface cleaning, coating removal and water-jet cutting, and because it is non-toxic, it is used for marine applications as well.

Garnet Is Cost-Effective

- As garnet is a very effective abrasive for cleaning. It is still possible to do an effective and complete job with a relatively low volume of garnet. As such, it is very cost-effective.

- Garnet is reusable and if carried out correctly, garnet can be used several times.

Garnet abrasives are particularly effective for:

- Aluminum and fiberglass structures

- Bridges, docks and shipyards

- Powder coating and denim blasting

- Industrial painting

- Hangar decks

- Confined spaces where low dusting is required

Standard packaging:

25 kg/bag & 1 MT per Jumbo Bag